Proven Quality Control Practices For Total Customer Satisfaction

We, at Scale Work, understand what is needed by our natural stone buyers. So, the quality process starts mid-way through the production process. We process marble, slate, quartzite, granite, limestone, and sandstone tiles, slabs, and natural stone. Our head office receives photos of production for checking. Each customer’s specification is checked. If some changes are required, these are implemented. After production is complete, the local quality officer sends a report to the head office. Around 30% of the containers are checked by quality control officers stationed at the head office. They travel to different parts of India, wherever the containers are packed, to check for quality. Every container with a special finish is also checked by quality inspectors. From quality control procedures to quality management practices, we leave nothing unnoticed.

We have stringent mandatory quality standards in place, and compliance is managed by timely independent external audits and internal assessments. These standards make sure that we plan, manufacture, and supply products that are safe, of high quality, and meet the applicable industry and regulatory standards in the countries where we operate. Comprehensive management procedures are in place to reduce risks and protect our buyers and markets.

Inspections

Pre and during production quality control checks

Quality is always a prerequisite at Scale Work. From extracting rough blocks to processing them at various stages, loading them into containers, and transporting them to their final destination — we strictly follow globally accepted quality parameters to deliver an industry-leading natural stone buying experience to our clients.

We have stringent mandatory quality standards in place, with compliance monitored through timely independent external audits and internal assessments. These standards ensure that we plan, manufacture, and supply products that are safe, high in quality, and aligned with the regulatory and industry norms of the countries we serve. Robust management procedures are implemented to reduce risks and safeguard our buyers and markets.

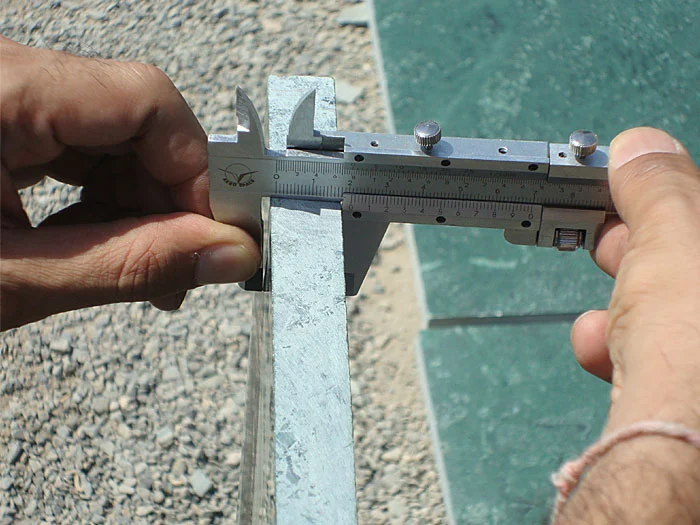

We carry out rigorous testing and monitoring at every stage of the manufacturing process. Our experienced quality control team uses advanced tools and techniques for cutting, shaping, polishing, and finishing — with close attention to detail. We inspect for structural integrity, surface finish, and dimensional precision. Any deviation from the desired specifications is corrected immediately, preventing issues from escalating further in the production cycle. This real-time quality monitoring allows us to detect and eliminate any potential defects before the product is finalized.

Our extensive industry experience and a team of skilled professionals give Scale Work a competitive edge in natural stone manufacturing and supply. To ensure optimal client satisfaction, we carry out detailed evaluations to confirm that all customer requirements are met. Any suggested changes are promptly shared with the production team, where necessary improvements and certifications are completed accordingly.

At Scale Work, we follow a unique quality control system built on strict manufacturing procedures to ensure flawless products. Our team of qualified, experienced, and dedicated professionals works diligently to maintain the effectiveness of our quality control measures.

We stay updated with the latest industry trends and are equipped with modern techniques to consistently deliver the best natural stone products to our customers. Our quality control analysts conduct rigorous checks at every stage of the production process.

At Scale Work, we are committed to delivering only high-quality, precision-crafted products that meet and exceed client expectations.